Introduction: The Dawn of Robotics in Food Packaging

In today’s rapidly evolving technological landscape, robotics has emerged as a transformative force across various sectors. One of the most intriguing applications is in the realm of food packaging within processing plants. This convergence of robotics and food packaging offers innovative potential poised to disrupt the traditional methods that have long dominated the industry. For entrepreneurs and startups, the field is ripe with possibilities for market disruption, yet it also presents distinct challenges that require strategic planning and execution.

The Innovation Potential of Robotics in Food Packaging

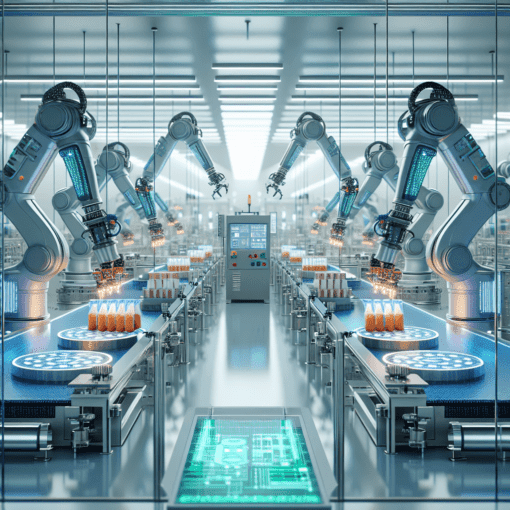

Automation in food packaging is not a new concept. However, advancements in robotics have taken this automation to new heights, allowing for more precision, speed, and efficiency. Modern robotics systems are equipped with advanced sensors and artificial intelligence (AI) capabilities, enabling them to handle delicate tasks with the kind of finesse that mirrors human workers but at a pace and accuracy unachievable by human hands alone.

Consider the example of Soft Robotics, a startup that designs robotic grippers using soft materials to handle irregularly shaped or fragile food items—a significant advancement over traditional, rigid robotic systems. Such innovations highlight the potential for robotics to revolutionize food packaging, tackling challenges of waste reduction, maintaining food safety standards, and improving overall process efficiency.

Market Disruption and the Rise of a New Paradigm

The integration of robotics into food packaging not only enhances operational efficiency but also disrupts the market by redefining the standards of production and distribution. Startups focused on this niche are pioneering new business models that leverage technology to reduce labor costs, increase throughput, and minimize human error. The use of robotics can significantly decrease the dependency on seasonal labor, often a logistical and financial burden for processing plants.

Startups like Apeel Sciences are changing the game by coupling robotic systems with innovative technologies—using plant-derived coatings to extend the shelf life of produce. This synergy facilitates a more sustainable approach to food packaging, further opening doors for entrepreneurs looking to develop holistic solutions in the food supply chain.

Key Challenges in Robotics for Food Packaging

Despite its promising potential, the field is not without its obstacles. One of the primary challenges is the significant upfront investment required for developing and deploying robotic systems. For startups, this necessitates a robust strategy for fundraising and securing adequate capital.

Moreover, achieving seamless integration of robotics into existing production lines can be technologically complex, requiring expertise in both robotics and food processing. This integration must be done without disrupting production workflows—a formidable task for any startup.

Another challenge lies in regulatory compliance. The food packaging industry is heavily regulated to ensure product safety, and robotics systems must adhere to stringent standards. This means that startups must navigate a labyrinth of regulatory frameworks to bring their products to market.

Unique Opportunities for Startups

While the challenges are significant, the opportunities for innovation and growth in this sector are equally plentiful. Robotics in food packaging offers startups a unique value proposition centered around efficiency, sustainability, and adaptability. By delivering tailored solutions that address specific needs within the supply chain, startups can differentiate themselves in a competitive market.

For instance, companies such as TOMRA Sorting Food have leveraged robotics to provide optical sorting systems that not only increase yield but also improve product quality. Such advancements not only appeal to processing plants looking to optimize operations but also to investors seeking promising ventures in food tech.

Strategies for Scaling and Achieving Product-Market Fit

For any startup, scaling is a critical step that calls for a well-defined strategy. In the context of robotics for food packaging, startups must focus on building scalable technologies that can adapt to various processing environments and product types.

Achieving product-market fit is another strategic imperative. Startups need to ensure their solutions align with industry needs by engaging with potential clients early on, understanding their pain points, and iterating their products based on feedback. This customer-centric approach can lead to more targeted solutions that resonate well within the market.

Moreover, forming strategic partnerships is crucial. Collaborations with established industry players can provide startups with valuable resources, including market insights, distribution networks, and technical expertise, all of which are vital for scaling operations.

Effective Fundraising Strategies

Securing funding is often the first hurdle for startups. Venture capital firms and angel investors are typically interested in startups with not only a novel product but also a strong business model and a clear path to profitability. Startups in the robotics space should be prepared to demonstrate the viability of their technology and its potential return on investment.

Participating in accelerator programs can also be an advantageous strategy. These programs can provide startups with mentorship, networking opportunities, and access to potential investors, increasing their chances of securing funding.

Customer Acquisition and Growth

In terms of customer acquisition, startups should leverage digital marketing strategies to reach a broader audience. Content marketing, coupled with social media outreach and search engine optimization (SEO), can help build brand awareness and attract prospective clients interested in cutting-edge food packaging solutions.

Furthermore, engaging directly with industry stakeholders through trade shows, webinars, and forums can facilitate direct connections with potential customers and partners, ultimately driving business growth.

Distinctive Aspects of Business Models and Technology

The business models emerging in this sector are diverse and innovative. Some startups are adopting a Robot-as-a-Service (RaaS) model, allowing companies to lease robots rather than purchasing them outright, significantly lowering the barrier to adoption.

On the technological front, startups are increasingly focusing on the integration of AI and machine learning to enhance the versatility and efficiency of robotic systems. This integration allows robots to learn from data, adapt to new tasks, and optimize processes in real-time, offering a competitive edge over traditional systems.

Case Studies: Success Stories in Robotics Food Packaging

Few examples shine brighter than the case of ABB Robotics, a leader in automation technologies. ABB’s solutions have been widely adopted across various sectors, and their innovations in food packaging have set new benchmarks for efficiency and quality. Their flexible robotic systems designed for high-speed pick and place operations are a testament to the impact of technological advancements.

Another notable success story is that of the Israeli startup Robotize, which entered the food packaging industry with an autonomous packaging robot capable of adapting to different packaging formats and sizes. Their innovative approach has not only garnered investments but has also been adopted by major food processing players, proving the effectiveness of their solution in a real-world context.

Academic Research and Industry Reports: A Foundation for Strategic Insights

To further substantiate the promise and challenges of robotics in food packaging, one must look at the wealth of academic research and industry reports available. A study published in the Journal of Food Engineering highlights the efficiency gains from robotic automation, documenting case studies where production speeds increased by up to 30% when robotics systems were implemented.

Furthermore, reports by organizations such as the International Federation of Robotics (IFR) provide detailed analyses of the robotics market, trends, and future projections, serving as a valuable resource for startups aiming to navigate this complex landscape.

Conclusion: A Future Shaped by Innovation

As we forge ahead into the future, the role of robotics in food packaging is set to expand exponentially. The industry is on the brink of a new era, wherein automation will not only redefine food packaging standards but also open new avenues for innovation and entrepreneurship. For startups and investors alike, this represents an exciting frontier—a confluence of technology and industry that promises to reshape the food packaging landscape in profound ways.

In summary, while the path may be fraught with challenges, those who can innovate within this exciting field will find immense opportunities to lead the charge in transforming the food packaging industry, driving sustainability, efficiency, and success in equal measure.