Advanced Robotics for Hazardous Environments: A New Frontier

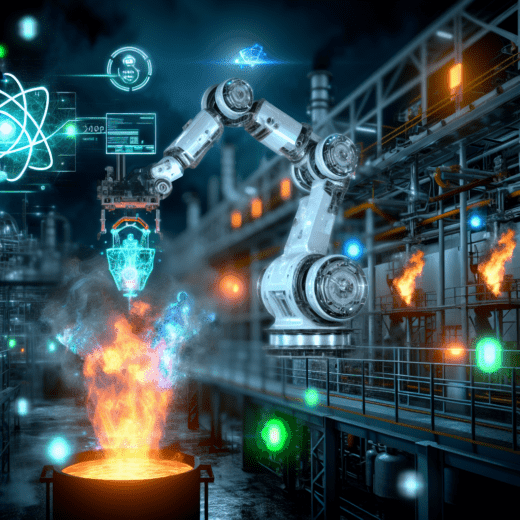

The thrilling advancements in robotics are rapidly transforming industries by automating tasks and enhancing productivity. Among the cutting-edge developments, advanced robotics designed for hazardous environments stand out due to their potential to revolutionize manufacturing processes, particularly in extreme or dangerous settings. This sector is replete with innovation potential, poised to cause substantial market disruption, and presents unique challenges and opportunities for startups looking to carve out a niche in this emerging field.

Innovation Potential in Advanced Robotics

The development of advanced robotics for hazardous environments signifies a major leap forward in technology and engineering. These robots are engineered to operate in conditions unsafe for humans, such as high temperatures, toxic atmospheres, or even underwater. By extending the capabilities of robotics beyond typical environments, startups can introduce solutions that not only enhance productivity but also ensure worker safety. The innovation potential here is immense, given the diversity of hazardous environments across various industries such as oil and gas, nuclear energy, and chemical manufacturing.

A particularly fascinating aspect of advanced robotics is its intersection with artificial intelligence (AI) and machine learning. These technologies allow robots to learn from their environment, adapt to new scenarios, and execute complex tasks with minimal human intervention. For example, Boston Dynamics’ Spot, an autonomous robotic dog, is deployed in construction sites to monitor progress, perform inspections, and ensure safety – tasks that might otherwise pose certain risks to human workers.

Market Disruption through Robotics

Integrating advanced robotics into hazardous environments is not merely about replacing manpower. It’s about redefining how industries approach challenging tasks. The shift towards robotics ushers in greater precision, consistency, and efficiency, drastically reducing errors associated with human operation. This technological upheaval can significantly lower costs over time, making industries more profitable and sustainable.

Moreover, robotics brings about a fundamental change in the labor market and workforce dynamics. As industries adopt advanced robots, there could be a shift towards more tech-focused roles, emphasizing the need for skilled technicians and engineers capable of designing, programming, and maintaining these sophisticated machines. This creates an opportunity for businesses and training institutions to develop programs that address the evolving needs of the workforce.

Key Challenges in Developing Robotics for Hazardous Environments

Despite the vast potential, developing robotics for hazardous environments poses several challenges. Primarily, the technology must be robust enough to withstand extreme conditions while maintaining optimal functionality. Materials used in constructing these robots have to be chosen carefully to ensure durability and longevity under stress, which can complicate design and increase manufacturing costs.

For startups, navigating the regulatory landscape presents another significant hurdle. Since these robots often operate in highly controlled industries like nuclear or chemical manufacturing, compliance with stringent safety standards is non-negotiable. Gaining the necessary certifications can be a long and resource-intensive process that demands meticulous planning and documentation.

Additionally, achieving interoperability with existing systems poses a technical challenge. Startups must ensure that their robotics solutions can easily integrate into an enterprise’s current technology stack, facilitating a seamless transition and minimizing disruption to business operations.

Strategies for Success in the Robotics Startup Ecosystem

For startups, succeeding in the hyper-competitive field of robotics, particularly within hazardous environments, requires a nuanced approach.

Fundraising: Securing adequate funding is essential for the substantial R&D investment that robotics demands. Startups should focus on crafting a compelling narrative that underscores the safety, efficiency, and cost benefits of their technology. Networking with venture capitalists specializing in deep tech or industrial applications can provide access to valuable resources and advice. Platforms like Kickstarter or AngelList might also present opportunities for crowdfunding, allowing entrepreneurs to gauge interest and obtain initial funds.

Scaling Operations: As the startup gains traction, scaling production becomes crucial. This entails not only optimizing manufacturing processes but also investing in a skilled workforce that understands the intricacies of robotics. Strategic partnerships with larger corporations or suppliers can facilitate scaling by providing access to better resources and distribution channels.

Achieving Product-Market Fit: Startups must identify and target the right industry verticals that benefit the most from their solutions. Conducting thorough market research and engaging potential clients early in the development process can provide insights into specific needs and preferences. Creating a versatile product line that can be customized for different scenarios will enhance broad appeal and drive adoption.

Customer Acquisition: A dual focus on B2B marketing and strategic partnerships can help startups establish a foothold in their chosen markets. Demonstrating the real-world value and ROI of robotics solutions through case studies and pilot programs can build trust and accelerate customer acquisition. Additionally, offering comprehensive training and support assures clients of seamless integration and effective operation of the technology.

Case Studies and Real-World Examples

Several startups have successfully penetrated the market with innovative robotics solutions. For instance, Sarcos Robotics, a pioneer in exoskeleton technology, has developed solutions specifically aimed at reducing human exposure to dangerous conditions. Their Guardian XO, a full-body, powered exoskeleton, is designed to augment human productivity while minimizing fatigue and injury risk in physically demanding environments.

Another success story is that of Q-Bot, which uses robots to improve energy efficiency in buildings. By deploying their robots in crawl spaces, Q-Bot can perform tasks such as spraying insulation, a job often considered impractical for human workers due to space constraints and health risks. These examples demonstrate the vast potential of robotics in expanding human capabilities and improving safety standards across industries.

Academic Research and Industry Insights

Research from institutions such as MIT and Stanford continues to push the boundaries of what’s possible with robotics. Academic studies often provide vital insights into material science advancements, AI integration, and new robotic design paradigms. These research endeavors often inspire startups in developing next-generation solutions catered to hazardous environments.

Industry reports from organizations like McKinsey or Boston Consulting Group provide forecasts and trends that can guide startups in strategic decision-making. Insights into market growth, technological adoption rates, and competitive landscapes are invaluable for startups aiming to position themselves effectively within the market.

Unique Business Models and Technologies

Startups in this niche often need to leverage unique business models and technologies to distinguish themselves. Subscription-based models or Robotics as a Service (RaaS) can provide continuous revenue streams while offering clients flexibility in upgrading and scaling their use of robotics technology. Such models align financial incentives between providers and customers, fostering long-term partnerships.

Emerging technologies, such as the Internet of Things (IoT), can enhance the functionality of advanced robotics by collecting real-time data that informs maintenance and operational improvements. Augmented Reality (AR) and Virtual Reality (VR) are also making inroads into robotics maintenance and training, offering immersive experiences that simplify complex processes.

Transitioning to a Safer, More Efficient Future

Ultimately, the development of advanced robotics for hazardous environments represents a significant step toward safer and more efficient industrial operations. Startups that successfully navigate the challenges and capitalize on the innovation potential can drive this transformation. By focusing on robust strategies, from effective fundraising to strategic partnerships, and keeping a pulse on industry trends and research, these companies can succeed in not only disrupting markets but also securing a safer future for workers across the globe.

The journey is fraught with challenges, but the opportunities are profound for those bold enough to push the boundaries of technology and redefine how industries approach hazardous environments. Continued exploration and investment in this sector promise not only lucrative returns but also significant advancements in how humans and machines collaborate to overcome the limits of safety and productivity.