Introduction

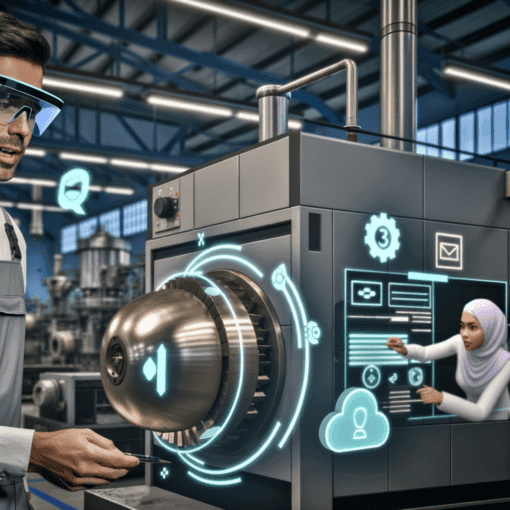

Augmented Reality (AR) has emerged as a transformative technology, promising to revolutionize various industrial sectors by bringing digital information directly into the physical environment. One of the most promising applications of AR is in machine maintenance, where AR tools help diagnose and troubleshoot machinery issues more efficiently and accurately. By merging the digital and physical worlds, AR can offer unprecedented insights and guidance, paving the way for significant improvements in industrial productivity and safety. This blog post delves into the innovative potential of AR Machine Maintenance Tools, examining their ability to disrupt markets, the challenges they face, and the unique opportunities available for startups.

Innovation Potential of AR in Machine Maintenance

AR technology facilitates a robust set of applications in machine maintenance, significantly transforming how technicians interact with machinery. This innovation enables technicians to visualize complex information, such as internal parts or workflow processes, directly on the machinery. As an embodiment of the Industry 4.0 vision, AR offers real-time, contextual data layered over physical equipment, thus assisting technicians in diagnosing and resolving issues more efficiently.

AR Machine Maintenance Tools can streamline the maintenance process by providing immediate access to digital manuals, annotations, and 3D simulations. For instance, technicians can wear AR headsets to receive step-by-step instructions while keeping their hands free. This simultaneously enhances efficiency and reduces downtime. Furthermore, AR can assist remote experts who guide onsite technicians in real-time, reducing travel costs and time delays.

An example of AR’s innovation potential is PTC’s Vuforia Studio, a platform enabling users to build AR experiences quickly. This tool allows companies to create step-by-step guides and overlay pertinent information on machines directly. Companies that harness such tools can expect significant ROI by cutting down operational delays and improving maintenance efficiency.

Market Disruption through AR Technology

AR’s potential to disrupt the machine maintenance market is immense. By enhancing operational efficiency and extending machinery life, AR adoption can profoundly affect sector economics. The traditional model, which often entails reactive maintenance and prolonged downtimes, can be turned on its head with AR tools facilitating predictive maintenance strategies. AR’s disruption is particularly pertinent in industries where machinery uptime directly correlates with profitability, such as manufacturing, logistics, and energy.

The growing integration of AR in machine maintenance also promises a shift towards predictive maintenance models. By visualizing machine analytics and using IoT data, AR can pre-emptively identify potential issues, allowing companies to conduct maintenance activities before failures occur. This proactive model minimizes unexpected downtimes and prolongs machinery life, resulting in better resource utilization.

Companies like Boeing and Lockheed Martin have already incorporated AR tools to aid in production processes and maintenance checks, seeing improvements in efficiency and accuracy. Boeing, for example, reported a 30% reduction in wiring production time using AR technologies. Such case studies highlight the potential for AR to disrupt traditional maintenance processes fundamentally.

Key Challenges in AR Implementation

While AR presents immense potential, startups venturing into this domain face several challenges. First is the technological barrier—AR systems require robust hardware such as advanced cameras, sensors, and display systems, which can be expensive. The integration with existing enterprise systems is also a significant hurdle, necessitating a seamless interface between AR applications and enterprise resource planning (ERP) systems.

Another challenge lies in data privacy and security. As AR systems potentially expose sensitive operational data, maintaining stringent security measures is critical. Startups must prioritize developing secure platforms that protect user data and mitigate risks associated with data breaches.

User adoption and training also pose significant challenges. While AR can simplify complex processes, it might be daunting for technicians unaccustomed to digital interfaces. Therefore, effective training programs are essential to enable a smooth transition and ensure widespread adoption.

Unique Opportunities for Startups

Despite these challenges, the AR market for machine maintenance brims with opportunities. The industry is ripe for innovation, offering startups the chance to introduce novel solutions that enhance value for end users. By focusing on niche markets or specific use cases, startups can carve out unique spaces and establish themselves as leaders in AR machine maintenance tools.

Startups can capitalize on data analytics and IoT integration to offer comprehensive solutions beyond mere visualization. By leveraging predictive analytics, startups can provide value-added services that offer proactive maintenance solutions, thereby differentiating themselves from competitors.

Strategic partnerships also present significant opportunities. By collaborating with established industry players, startups can accelerate their market entry, gain access to distribution networks, and enhance their credibility. Partnering with hardware manufacturers can also offset the challenge of initial hardware costs and promote mutual growth.

Strategies for Success

Fundraising:

Startups in the AR space must effectively strategize their fundraising efforts. Communicating the immense potential of AR applications in machine maintenance to investors is crucial. Demonstrating a clear business model, well-defined market strategy, and solid value proposition can attract investment. Moreover, showcasing pilot projects or early customer successes can build investor confidence, illustrating the startup’s capability to execute its vision.

Scaling:

Scaling an AR startup involves not only enhancing customer base and market presence but also building scalable technology infrastructure. Startups should prioritize modular and adaptable technology architectures that can handle increased scale without compromising performance. Collaborative tools and agile development methodologies can further enhance scalability, facilitating seamless expansion into new markets or verticals.

Additionally, geographic expansion can be a potent strategy for scaling. By identifying international markets with a demand for advanced maintenance solutions, startups can replicate domestic success globally, with localized modifications to meet regional requirements.

Achieving Product-Market Fit:

Product-market fit is crucial for any technology-driven startup. AR startups should rigorously test their products through real-world applications to refine their offerings. Feedback loops with early adopters can provide critical insights that inform product development, ensuring the solution aligns with market needs.

A focus on usability is critical; AR solutions should deliver tangible benefits without overly complex user interfaces. Attaining product-market fit often requires iterative development, incorporating user feedback into product iterations to optimize features and usability.

Customer Acquisition:

Effective customer acquisition strategies entail identifying the right customer segments and employing targeted marketing campaigns. B2B marketing channels, partnerships with industry influencers, and participation in industry conferences can aid in building brand awareness and credibility. Providing trial periods or pilot programs can also encourage potential clients to explore AR solutions without commitment, demonstrating their value firsthand.

It’s essential to build a feedback-rich relationship with initial customers, who can become advocates for the technology when satisfied with the results. Leveraging case studies and customer testimonials can amplify marketing efforts, establishing the startup as a trusted player in AR machine maintenance.

Distinctive Business Models in AR Startups

Successful AR startups often differentiate themselves through distinctive business models. Subscription-based models can provide steady revenue streams while allowing clients flexibility in adopting AR solutions. Alternatively, performance-based pricing models can offer shared risk and rewards—charging clients based on the actual efficiency improvements realized through AR tools.

Developing a partner ecosystem also contributes to a robust business model. Establishing a network of complementary solutions and services can create a holistic platform for clients, enhancing the value proposition and fostering customer loyalty. Moreover, investing in community-building initiatives such as developer forums or training programs can augment brand presence and establish the startup as an industry thought leader.

Case Studies and Examples

Several startups exemplify successful implementation of AR in machine maintenance. For instance, Scope AR delivers solutions that leverage real-time input using smart glasses to guide technicians through complex tasks. Their tools have been employed by organizations such as Unilever, enhancing maintenance operations efficiency and effectiveness. Similarly, Augmentir offers an augmented operations platform that combines AR with artificial intelligence, optimizing field service efficiency through enhanced data-driven insights.

Academic research and industry reports further reinforce AR’s potential. Reports by firms such as Deloitte and McKinsey highlight AR’s projected influence on industrial sectors, citing enhanced productivity and improved maintenance workflows as substantial benefits. These insights offer strategic guidance for startups seeking to leverage AR in machine maintenance.

Conclusion

Augmented Reality is poised to transform the landscape of machine maintenance, offering potent tools that can significantly improve efficiency, safety, and operational uptime. The journey for startups in this space involves navigating technological challenges, securing funding, scaling effectively, and achieving product-market fit. However, the opportunities for innovation and market disruption are vast, with strategic execution opening remarkable potential for growth.

By focusing on user-centric solutions and adopting innovative business models, AR startups can redefine machine maintenance paradigms, turning challenges into avenues for success. As the AR industry continues to mature, its role in machine maintenance will likely become indispensable, solidifying its position as a key driver of Industry 4.0 and beyond.