Understanding Robotic Palletizing Systems

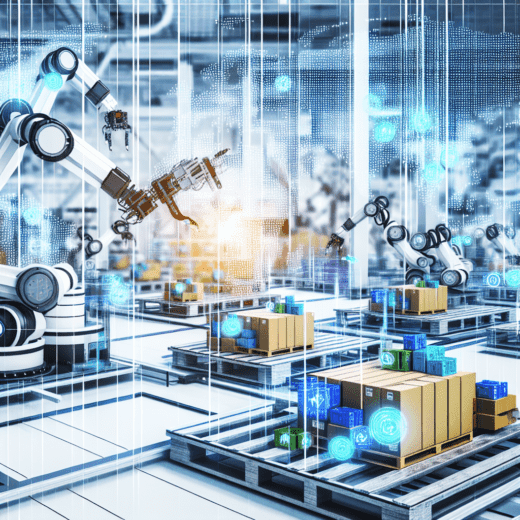

As automation continues to transform industries across the globe, robotic palletizing systems have emerged at the forefront of innovation in manufacturing settings. These systems automate the stacking of goods on pallets, a task traditionally performed by human laborers. With rapid advancements in technology, these automated systems are not only enhancing efficiency but are also reshaping competitive landscapes across various sectors.

Innovation Potential and Market Disruption

Robotic palletizing systems represent a significant innovation with the potential to disrupt traditional manufacturing and logistics processes. Automation in palletizing is reducing human error, enhancing speed, and improving the precision with which goods are stacked. Traditional methods often entail monotonous, labor-intensive tasks that can lead to worker fatigue and potential injuries. By contrast, robotic systems can operate around the clock with unmatched consistency and safety.

The market for robotic palletizing is on a growth trajectory, bolstered by increasing demand for automation and the advent of smart factories. These systems are versatile, capable of being integrated into existing production lines, and adaptable to a wide variety of products. They support a seamless transition from manual to automated processes, offering a robust solution that scales with business growth. This adaptability makes them an attractive proposition for startups aiming to break into the logistics and manufacturing sectors.

Key Challenges in the Startup Ecosystem

While the promise of robotic palletizing systems is profound, startups in this sector face several key challenges. Developing a sophisticated product that caters to the specific needs of different industries requires significant research and development. Ensuring that these systems can handle diverse product weights, sizes, and materials without compromising efficiency is a technological hurdle that demands continuous innovation.

Another major challenge is the integration of robotic palletizing systems within legacy systems. Startups must design products that can be easily incorporated into existing infrastructures without costly overhauls. This involves understanding the complexities of different industrial environments and developing systems that can communicate with existing machinery and software.

Strategizing for Success

Fundraising and Scaling

For startups, securing adequate funding is crucial to advance technological development and drive market penetration. Given the capital-intensive nature of developing robotic systems, attracting venture capital or forming strategic partnerships is essential. Engaging with investors who have a clear understanding of the technology and market dynamics is beneficial. Success stories, such as Fetch Robotics, which raised $46 million in a Series C funding round, highlight the importance of convincing investors of the scalable potential of these systems.

Scaling a business in the robotic palletizing field involves expanding both production capabilities and market reach. This requires not only financial resources but also strategic planning in terms of supply chain management and operational logistics. Building strong relationships with suppliers and manufacturing partners can ensure steady growth while maintaining production quality and meeting customer demands.

Achieving Product-Market Fit

Achieving product-market fit in the robotic palletizing industry involves a comprehensive understanding of the market needs and developing a product that meets those demands. Startups can achieve this by maintaining close communication with potential clients, seeking their input during the development process, and iterating the product based on feedback. This was exemplified by Rethink Robotics, whose collaborative robots (cobots) were designed by closely studying user needs and preferences, establishing a strong product-market fit that facilitated its success.

Customer Acquisition

An effective customer acquisition strategy involves demonstrating the tangible benefits of robotic palletizing systems, including improved operational efficiency, cost savings, and enhanced safety. Developing case studies, hosting demos, and offering trials can effectively showcase the superiority of these systems over traditional methods. Utilizing digital marketing strategies to reach target audiences, such as manufacturing firms and logistics companies, also plays a critical role in driving customer engagement.

Opportunities in Robotics and Automation

Startups venturing into robotic palletizing benefit from the broader trends towards automation and Industry 4.0. There is immense potential in leveraging artificial intelligence and machine learning to enhance the decision-making capabilities of these systems, making them more flexible and adaptable to changing production requirements. Innovating in the realm of software capabilities enables startups to provide customizable solutions tailored to meet specific customer needs, thus opening doors to new markets.

Case Studies and Real-World Examples

To illustrate the successful application of robotic palletizing systems, it is helpful to consider notable case studies. For instance, ABB Robotics’ deployment of the IRB 460, known for its speed and precision, exemplifies how automation can revolutionize a manufacturing line. Similarly, startups like Universal Robots have made significant inroads with their easy-to-use collaborative robots, showcasing how startups can effectively carve out a niche market by focusing on accessibility and user-friendliness.

Academic and Industry Insights

Numerous academic studies and industry reports underline the transformative potential of robotic palletizing. Research by the International Federation of Robotics (IFR) suggests an upward trend in the adoption of industrial robots, driven largely by the need to enhance productivity and ensure operational safety. Industry insights from reports by McKinsey & Company highlight how automation is becoming a strategic priority for companies seeking competitive advantages in a digitized economy.

Conclusion

The realm of robotic palletizing systems presents a fertile ground for startups to innovate and disrupt the established order of manufacturing and logistics. By harnessing cutting-edge technology and navigating the challenges of the startup ecosystem, entrepreneurs can tap into vast market opportunities. Strategic fundraising, effective scaling, achieving product-market fit, and adept customer acquisition strategies form the backbone of success in this burgeoning industry. As the automation wave continues to surge forward, robotic palletizing systems are set to play an increasingly pivotal role in shaping the future of industrial operations.