Understanding Factory Robotics for Mass Customization

Manufacturing has undergone a seismic shift in recent decades, particularly influenced by the growing demand for greater product variance and personalization. Traditional methods, focusing on large-scale production of uniform items, clash with current consumer desires for customized products. This is where the advancement of robotics plays a pivotal role in manufacturing, enabling the concept of “mass customization.” By integrating robotic systems designed specifically for this purpose, manufacturers can achieve the flexibility and efficiency needed to produce customized products on a mass scale.

The Innovation Potential in Factory Robotics

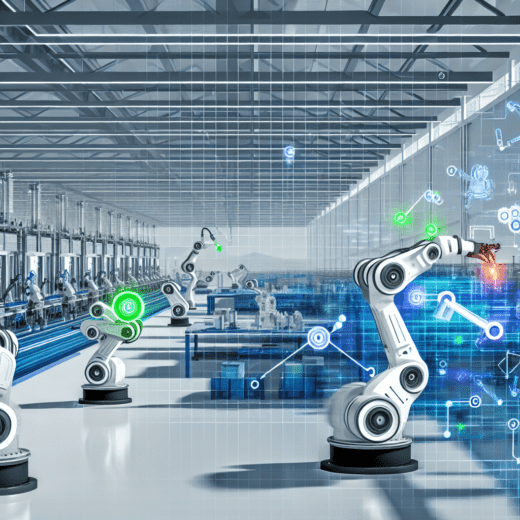

Robots in manufacturing are not a novel concept. However, designing robotic systems that support mass customization elevates their function beyond repetitive tasks to a more sophisticated, adaptable form. This innovation is fuelled by breakthroughs in artificial intelligence, machine learning, and sensor technology, which empower robots to think, adapt, and learn. Unlike static production lines, these advanced systems can handle a variety of tasks, from assembling completely different components to seamlessly switching their operations for producing customized products.

The potential of innovation in this area is profound. Mass customization through robotics allows manufacturers to not only meet diverse customer demands but also to reduce production costs and time-to-market for new offerings. This adaptability is vital in today’s fast-paced market, where companies constantly vie to introduce the next big thing. Furthermore, such systems can enhance sustainability by minimizing waste, as robots precisely use materials tailored to bespoke product requirements, minimizing offcuts and excess production.

Market Disruption and Opportunities

The move toward robot-enabled mass customization is disruptive and rife with opportunities. Startups in this space have the chance to fundamentally redefine manufacturing processes. The shift is evident across various industries, from automotive to apparel, thereby generating a ripple effect across the supply chain. Startups that develop or implement these robotic systems can capture market segments looking for rapid and flexible production solutions.

Take automotive manufacturing, for instance, where customization has become a significant selling point. Customers relish the idea of tailoring their cars with unique features. Robotics has turned this desire into a functional reality, supporting assembly lines that cater to highly individualized car specifications without sacrificing efficiency. Similarly, in the apparel industry, robotic systems now enable the creation of unique garments crafted to individual measurements, cutting down on unnecessary stock and promoting sustainable practices.

Challenges in Designing Robotic Systems for Customization

Despite their potential, developing robotic systems for mass customization isn’t without significant challenges. Key among them is the complexity of programming robots to handle a range of tasks initially designed for human dexterity and decision-making. Moreover, integrating robotics into already existing manufacturing lines presents logistical and technological challenges, including interoperability and predictive maintenance.

Another major hurdle is cost. The development and implementation of these advanced robotic systems require substantial capital investment. This financial barrier can be particularly daunting for startups trying to break into the market. Furthermore, the rapid pace of technological advancement necessitates continuous investment in updating both hardware and software, perpetually raising the financial stakes.

Key Strategies for Success in the Startup Ecosystem

Navigating the path from inception to market leadership requires startups to master several strategic aspects:

Fundraising and Financial Strategy

Securing funding is critical for any startup, especially those in tech-heavy industries like factory robotics. Ventures in this space often require substantial upfront capital to fund research and development, prototyping, and testing. Successful startups often attract venture capital by showcasing robust business plans that highlight innovation, potential market impact, and scalability.

Take the example of Rethink Robotics, which gained attention with their development of intelligent, collaborative robots (cobots). By presenting clear market differentiators and scalability potential, they successfully secured significant venture capital investments. Moreover, strategic partnerships can serve as dual pathways for funding and technical collaboration. Partnering with established firms can provide startups not only with financial resources but also access to invaluable industry insights and technological infrastructures.

Achieving Product-Market Fit

For startups in factory robotics, achieving product-market fit is pivotal. This involves not only developing a product that customers want but ensuring it aligns with the current manufacturing needs and capabilities. Conducting thorough market research to understand specific industry demands and pain points can guide product development. A pertinent case is Bright Machines, utilizing its micro-factories to offer solutions that directly meet the needs of their industrial partners for scalable, flexible automation.

Customer Acquisition and Retention

Acquiring customers in a niche market like robotic manufacturing requires a deep understanding of industry-specific needs. Startups should leverage case studies and pilot programs to demonstrate the tangible benefits of their systems. Testimonials from reputable early adopters can significantly enhance credibility. Thereafter, cultivating strong relationships is essential to retain these customers, achieved by offering exceptional post-installation service and continuous product enhancement.

Unique Startup Models and Technologies

Successful startups often rely on distinctive business models and technologies. Some leverage a “Robotics-as-a-Service” (RaaS) model, allowing manufacturers to subscribe to robotic solutions without the massive capital expenditure. Others focus on developing AI-driven software platforms that enhance robot intelligence and efficiency, much like Universal Robots, whose intuitive programming and versatility have redefined collaborative industrial robots’ roles.

Real-World Case Studies and Success Stories

Examining real-world examples offers insightful lessons. Take General Electric’s “Brilliant Factory” initiative, which integrates machine learning and analytics with physical production processes. By employing sensor-rich robotic systems, they achieved a notable increase in production efficiency and quality control. This initiative came to fruition through strategic investments and collaborations, emphasizing the importance of synergies in driving innovation.

Similarly, a startup named Vention has disrupted the market with its cloud-based platform, allowing users to design custom factory equipment using pre-engineered modular components. This innovation reduces the lead time for manufacturing technology significantly, showcasing how addressing specific pain points can create value and disrupt traditional practices.

Conclusion

Factory robotics for mass customization presents a transformative opportunity in the manufacturing sector. By designing robotic systems that enable flexibility and efficiency, startups can meet the modern demand for individuality without compromising on scale. The journey, however, is laden with challenges including high costs and technical complexities. Armed with strategic approaches in fundraising, market exploration, and customer engagement, dedicated entrepreneurs can create products that not only disrupt current markets but also set the foundation for the smart factories of the future. Each obstacle presents a learning point, and each innovation an unprecedented opportunity, marking this space as one of the most dynamic and promising in the tech startup ecosystem today.