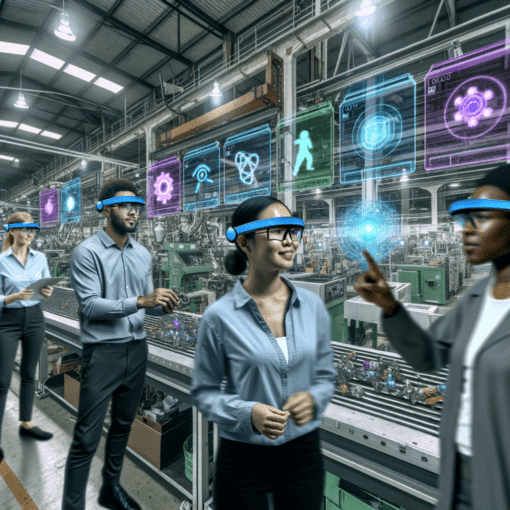

Introduction to Augmented Reality in Assembly Lines

Augmented Reality (AR) is transforming industries by overlaying digital information onto the real world. In manufacturing, AR is particularly valuable, offering assembly line workers real-time guidance and enhancing productivity. AR Assembly Line Guidance provides augmented reality guides to help workers perform tasks more efficiently, reducing errors and improving quality control. This innovative solution combines technology with practical applications, revolutionizing how manufacturers operate.

Innovation Potential and Market Disruption

The potential of AR in assembly line guidance is vast, heralding a new era of industrial innovation. Industry 4.0 concepts, such as smart factories and IoT, are fundamentally changing manufacturing processes. AR complements these changes by integrating seamlessly into existing production environments and offering a competitive advantage. By bringing digital instructions directly to workers’ line of sight, AR minimizes the need for physical manuals and complex training sessions.

The disruption potential lies in its ability to reduce downtime and enhance assembly precision, setting new benchmarks for operational efficiency. Companies that adopt AR technology enjoy improved quality assurance, as precision guidance reduces human errors. A study by PWC reveals that early adopters of AR technology have experienced productivity gains of up to 32%. This reflects not only an improvement in manufacturing efficiency but also an increase in output quality, which can differentiate firms in a competitive marketplace.

Key Challenges in Implementing AR Technology

While the advantages are considerable, the adoption of AR in assembly lines is fraught with challenges. One major hurdle is the high initial investment needed for AR infrastructure. Startups in this space need to balance technological advancements with cost efficiency to convince manufacturers of the financial viability of these solutions. Moreover, integrating AR into existing systems requires extensive compatibility checks and potential-overhaul of legacy systems, which can be both time-consuming and expensive.

Another challenge involves workforce adaptation. Skilled workers accustomed to traditional methods may be resistant to change, requiring comprehensive training programs. The success of AR technology relies on its usability; if workers find it cumbersome, its efficiency benefits are negated. Moreover, privacy concerns arise with the potential tracking of workers’ movements and data, necessitating clear policies and ethical guidelines.

Unique Opportunities in the Startup Space

For startups, the AR assembly guidance technology presents unique opportunities. The ability to innovate and differentiate in a crowded market opens doors to securing early adopter clients. Establishing a clear value proposition is essential for startups to thrive. For instance, highlighting the cost savings from error reduction and improved assembly speed can attract manufacturers wary of initial investments.

Opportunities also exist in developing complementary technologies such as machine learning algorithms that analyze assembly line data to provide predictive maintenance insights or workflow enhancements. Startups have the advantage of agility, allowing them to rapidly iterate and tailor their solutions to meet specific industry needs.

Collaboration with established AR hardware providers can offer another avenue for startups looking to enhance their offerings. By integrating cutting-edge hardware with sophisticated software solutions, startups can create comprehensive packages that address multiple aspects of assembly line efficiency and productivity.

Strategies for Success: Fundraising and Scaling

Successful implementation of AR technologies requires substantial funding. Startups should engage with venture capitalists and angel investors specialized in the technology sector. Demonstrating strong potential for rapid growth and scalability is key. An effective pitch would focus on real-world case studies showing proven effectiveness of AR guidance in improving efficiency and reducing costs.

Once initial funding is secured, scaling effectively becomes the next priority. This involves expanding the technology to different manufacturing sectors, such as automotive, electronics, and aerospace, which have complex assembly processes. Partnerships with sector-specific experts can offer critical insights and facilitate smoother transitions into these specialized markets.

Moreover, adopting a SaaS (Software as a Service) model can provide continuous revenue streams, allowing businesses to scale sustainably. By offering subscription-based services, startups can cater to varying customer needs, providing basic offerings for smaller businesses and premium packages for large manufacturers.

Achieving Product-Market Fit

Achieving product-market fit is a critical step for any startup. For AR assembly line guidance systems, this means ensuring that the technology is intuitive, effective, and addresses the specific pain points of target customers. Engaging with potential users during the development phase to gather actionable feedback can guide product refinement.

Furthermore, acting on detailed market research provides understanding of customer needs and preferences. Identifying market segments that are ripe for disruption, such as those with high error rates and training costs, allows startups to tailor their solutions effectively.

Collaborations with industry leaders for pilot projects can also validate the product’s utility and effectiveness, providing crucial proof-of-concept data for potential customers and investors alike. Entry into strategic partnerships with firms undergoing digital transformation initiatives can also help fine-tune the product to achieve a better market alignment.

Customer Acquisition and Retention Strategies

Marketing plays a crucial role in acquiring customers for AR assembly guidance startups. An integrated marketing strategy that leverages digital channels is vital. Content marketing, showcasing the technology through webinars, whitepapers, and blog posts, helps educate potential customers about the benefits of AR in assembly lines.

Networking with industry stakeholders by participating in industrial conferences and trade shows increases visibility and credibility. Demonstrating the technology live allows potential customers to experience firsthand the benefits of AR guidance.

Retention is equally important, and providing excellent customer service helps maintain strong relationships. Regular updates and improvements based on customer feedback show a commitment to evolving technology and addressing users’ changing needs.

In addition, creating a community of users can offer valuable peer support, facilitating the exchange of tips and troubleshooting advice. This approach not only enhances customer satisfaction but also engenders loyalty by building a network of engaged users.

Case Studies: Real-World Examples

A successful case study example is Boeing’s use of AR to guide technicians in wiring aircraft. Implementing AR reduced production time by 25% and diminished errors significantly. The AR system provided real-time, layered instructions, allowing for more precise and efficient task execution.

Another example is Porsche, which uses AR glasses to improve technical service and assembly processes. The glasses overlay digital repair manuals and guides, enabling workers to follow instructions without removing their focus from the task at hand. Porsche reported considerable savings in time and improved service speed, underlining the practical utility of AR technology.

These cases illustrate the tangible benefits AR can bring to assembly lines and underline the immense potential for startups in this space.

Conclusion: The Future of AR in Assembly Lines

As industries continue their digital transformation journeys, AR assembly line guidance represents a frontier of potential. This technology not only simplifies complex manufacturing processes but also provides room for continuous improvement and innovation. The path for startups in this field is promising, characterized by challenges that, when overcome, offer significant rewards.

Startups that focus on strategic growth, building robust partnerships, and ensuring a strong product-market fit are poised to capture substantial market opportunities. With the right approach, AR has the power to redefine manufacturing norms, leading an industrial paradigm shift that aligns with the principles of efficiency, precision, and innovation.

Embracing this technology is not just about keeping up with modern trends but about setting benchmarks for future advancements in manufacturing and beyond. As augmented reality continues to evolve, its impact on assembly lines is set to increase, making it a crucial focus area for innovators looking to stake their claims in the future of industry.