Introduction

In the rapidly evolving landscape of technology, augmented reality (AR) and virtual reality (VR) have emerged as potent tools for transforming industries. Their integration into remote factory management is poised to revolutionize how manufacturing plants operate, offering unprecedented levels of monitoring and control. This blog post delves into the potential for innovation, market disruption, key challenges, and unique opportunities in the startup ecosystem. It will explore strategies for success including fundraising, scaling, achieving product-market fit, and customer acquisition. Additionally, real-world case studies and industry reports will illuminate the path for entrepreneurs, investors, and tech enthusiasts interested in capitalizing on this technological frontier.

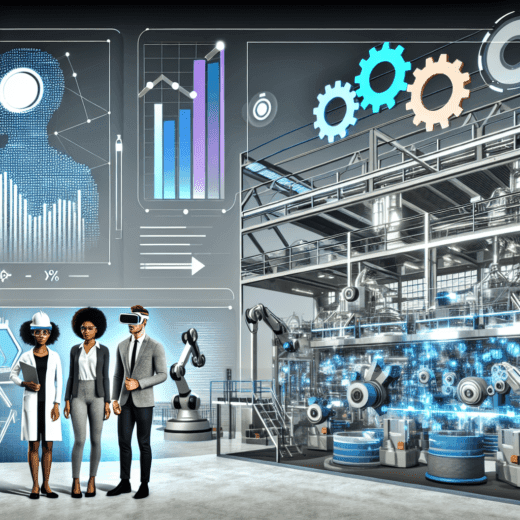

The Innovation Potential of AR/VR in Remote Factory Management

Revolutionizing Manufacturing Operations

AR and VR technologies offer transformative potential by enhancing visibility and control over manufacturing processes. Through immersive simulations and real-time data overlays, factory managers can oversee operations remotely, ensuring efficiency and mitigating risks. The integration of these technologies enables engineers to visualize complex assembly lines, troubleshoot issues instantly, and collaborate seamlessly with teams spread across different locations.

For instance, AR can facilitate the digitization of factory layouts, providing managers with immediate insights into production metrics and equipment health. This kind of visualization aids in predictive maintenance, reducing downtime and optimizing performance. With VR, training programs can become more immersive and effective, allowing workers to practice in virtual environments before transitioning to the actual floor.

Real-World Application: Case Study – Siemens

Siemens, a leader in automation solutions, has successfully employed AR for remote monitoring. Their AR platforms facilitate remote diagnostics and maintenance, providing technicians with detailed visual information and guidance. This has not only decreased response times but also significantly cut down operational costs, setting a precedent for other firms in the industry.

Market Disruption Enabled by AR/VR Technologies

Changing Competitive Dynamics

The incorporation of AR/VR in factory management introduces a new competitive paradigm. Traditional manufacturers are being challenged by startups that can quickly adapt and integrate these technologies into their systems, increasing operational agility and reducing costs. This shift is propelling the manufacturing sector towards more intelligent and responsive setups, where decisions are data-driven and highly automated.

Furthermore, the democratization of AR/VR technology through increasingly affordable hardware and software solutions contributes to a more level playing field. Startups that leverage these technologies can offer customized solutions, targeting niche markets that established players may overlook due to their focus on mass production.

Emerging Market Leaders: Case Study – PTC’s Vuforia

PTC’s Vuforia platform demonstrates how startups can capitalize on AR/VR for industrial applications. Vuforia’s tools enable developers to rapidly deploy AR applications for a range of manufacturing tasks, providing innovation without the heavy infrastructural costs associated with traditional manufacturing transformation. This agility enables startups to disrupt older market structures, capturing substantial market share in the process.

Key Challenges in Implementing AR/VR Solutions

Technical and Operational Hurdles

Despite its potential, implementing AR/VR solutions in manufacturing faces significant challenges. Technical obstacles include compatibility issues with existing IT infrastructure, data security concerns, and the need for robust connectivity to ensure real-time updates. Operationally, there is the challenge of re-skilling workers accustomed to traditional methods and aligning AR/VR strategies with broader business goals.

Additionally, resistance to change can be a significant barrier. For AR/VR to be successfully integrated, buy-in is required at all levels of the organization, from frontline workers to C-suite executives. Aligning vision and securing endorsement from leadership is crucial in overcoming these challenges and fostering an environment conducive to innovation.

Addressing Challenges: Case Study – Lockheed Martin

Lockheed Martin has been at the forefront of employing AR to enhance assembly processes. By adopting a phased approach that includes extensive worker training and upskilling, they have successfully addressed many operational challenges. Their use of AR glasses for real-time assembly instructions has reduced error rates and improved overall production efficiency, illustrating a successful implementation strategy.

Unique Opportunities for Startups in the AR/VR Space

Innovation and Customization

Startups are uniquely positioned to exploit the flexibility of AR/VR solutions. Unlike established corporations with rigid structures, startups can tailor these technologies to meet specific client needs, offering bespoke solutions that address particular pain points. This agility allows startups to create novel business models and revenue streams, such as subscription-based AR/VR software platforms or a-la-carte customization services.

Additionally, startups can leverage the data generated through AR/VR systems to provide value-added services, such as predictive analytics and process optimization recommendations. By integrating machine learning algorithms with AR/VR data, startups can help manufacturers further refine their operations, leading to improved efficiency and innovation.

Success Story: Case Study – Augmentir

Augmentir, a startup specializing in AI-driven workforce optimization, has harnessed the power of AR to enhance manufacturing operations. Their solutions provide intelligent insights into workforce performance, leveraging AR to deliver situational awareness and task guidance. Augmentir’s customizable platform enables companies to create tailored workflows, demonstrating how startups can innovate within this space effectively.

Critical Strategies for Startup Success

Fundraising and Investment Approaches

For startups working in AR/VR for manufacturing, securing funding is a significant hurdle. However, the rapidly growing interest in industry 4.0 solutions presents opportunities for investment. Startups must articulate a clear value proposition and demonstrate tangible benefits to investors, highlighting cost reduction and efficiency improvements. Engaging with venture capital firms that have a track record in industrial tech can provide not only capital but also valuable industry connections and expertise.

Building partnerships with established players can also be beneficial. Collaborations can enhance credibility, open distribution channels, and accelerate technology development. Strategic alliances with hardware manufacturers and software integrators can provide the technical support and market reach essential for scaling operations.

Achieving Product-Market Fit

Achieving product-market fit involves understanding the specific challenges manufacturers face and addressing them with precise, AR/VR-enabled solutions. Conducting market research and engaging with potential customers during the development process ensures that the product aligns with market needs and expectations. Iteratively refining the product based on user feedback can enhance usability and spur adoption.

Furthermore, startups should focus on cumulative improvements rather than disruptive overhauls. Integrating AR/VR as complementary tools to existing processes facilitates smoother adoption by minimizing disruption to current workflows.

Scaling and Customer Acquisition

Scaling requires startups to replicate initial successes across diverse manufacturing verticals. Building a strong brand identity and demonstrating a track record of ROI will be crucial in attracting new customers. Startups can benefit from a targeted marketing approach, focusing on industries with the highest potential for AR/VR applications such as automotive, aerospace, and electronics manufacturing.

Customer acquisition can be accelerated by offering pilot programs or proof-of-concept trials that showcase the technology’s benefits firsthand. By providing customers with a risk-free trial period, startups can foster trust and demonstrate tangible value before committing to full-scale adoption.

The Distinctive Business Models of AR/VR Startups

Platform-Based Models

Some AR/VR startups are adopting platform-based business models, offering scalable software solutions that integrate seamlessly with various hardware. This model allows startups to capture value by building an ecosystem that supports a wide array of third-party applications. Subscription-based access not only provides a steady revenue stream but also allows for continuous customer engagement and iterative product enhancements based on user feedback.

Outcome-Based Models

Another emerging trend is the outcome-based business model, where the startup’s revenue is directly tied to the customer’s performance improvements. This model aligns the interests of the startup with their client’s goals, fostering a partnership approach. By pricing based on metrics like efficiency gains or cost savings, startups can ensure customer satisfaction and encourage long-term relationships.

Conclusion

The synergy of AR/VR technologies with remote factory management holds immense potential to reshape the manufacturing landscape. For startups willing to navigate the complexities of this industry, significant opportunities await in driving innovation and disruption. By leveraging strategic partnerships, refining business models, and focusing on customer-centric development, emerging companies can carve out a competitive niche in the industrial technology ecosystem. As more case studies and success stories emerge, the path forward becomes clearer, illustrating how AR/VR is not just a transformative force, but a vital component of the future of manufacturing. Whether you’re an entrepreneur seeking to disrupt the market, an investor sizing up the next big opportunity, or a tech enthusiast marveling at the pace of innovation, the integration of AR/VR into manufacturing offers a thrilling glimpse into the future of industry.