The Rise of Construction Robotics in Automating Processes Like Bricklaying and Plastering

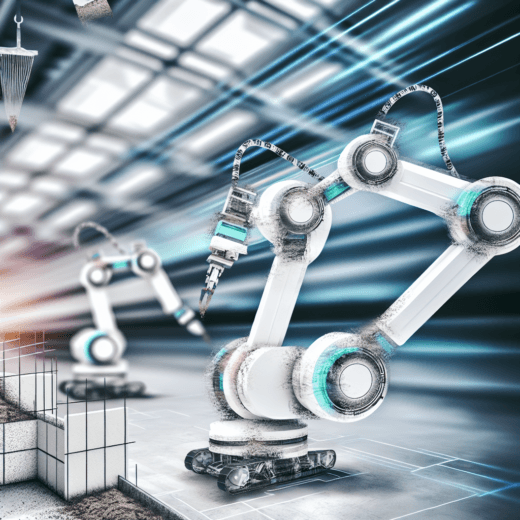

In recent years, the field of construction has been experiencing a technological revolution, particularly with the advent of construction robotics. This refers to the integration of automation and robotics in construction processes to enhance efficiency, safety, and productivity. With a focus on specific tasks such as bricklaying and plastering, construction robotics presents a promising frontier for startups looking to innovate and disrupt the traditional industry landscape.

Innovation Potential in Construction Robotics

At the heart of construction robotics lies enormous innovation potential. The construction industry, known for its manual labor-intensive processes, has lagged in adopting automation compared to other sectors like manufacturing and logistics. However, the integration of robotics offers unprecedented opportunities to transform how construction projects are executed. Robotics can mitigate challenges such as labor shortages, skill gaps, and the need for precision on construction sites.

Construction robots can perform repetitive tasks with high accuracy and speed, significantly reducing the time required for completion. For instance, bricklaying robots are capable of laying hundreds of bricks per hour, a task that would otherwise demand considerable manual effort and time. Plastering robots, on the other hand, ensure uniform application of plaster, reducing material wastage and improving surface quality. Startups in this space can leverage these capabilities to develop products that offer quantifiable improvements in construction project metrics.

Market Disruption and Industry Shifts

The introduction of robotics into construction processes like bricklaying and plastering is a disruptive force that is reshaping the construction industry. Traditionally, these tasks required skilled labor, extensive training, and constant quality supervision. Today, construction robotics presents a scenario where the workforce can be guided towards supervisory roles, allowing robots to handle the more laborious and precise aspects.

This shift is not merely about replacing manpower with machines but is about enhancing the existing workforce. By automating routine tasks, construction professionals can focus on complex problem-solving and project management, leading to better overall project outcomes. For startups, this disruption is both an opportunity and a challenge, as they must navigate industry resistance, regulatory landscapes, and invest in workforce retraining programs to ease the transition.

Key Challenges in Construction Robotics Development

Despite its potential, the journey to integrate construction robotics is fraught with challenges. One major challenge is the high cost of development and deployment. Research and development in robotics require significant investment in technology, engineering talent, and prototyping. Startups must balance these costs with the need to develop competitive products that are economically viable for end-users.

Moreover, construction sites are diverse and unpredictable environments, with varied tasks, terrains, and requirements. Robots designed for construction purposes must be highly adaptable and robust to function effectively across different settings. This calls for advanced sensor technologies, AI-driven decision-making capabilities, and flexible hardware designs, adding layers of complexity to the development process.

Another challenge is gaining trust and acceptance from the construction industry, which has traditionally been cautious in adopting new technologies. Convincing stakeholders of the reliability and benefits of robotic solutions requires demonstrable case studies, pilot programs, and effective communication strategies.

Unique Opportunities for Startups

While the challenges are significant, the opportunities for startups in the construction robotics domain are equally compelling. For one, the growing focus on sustainability and efficiency in construction creates a demand for automation solutions that can minimize resource consumption and enhance building quality. Startups can position themselves as pioneers in developing eco-friendly robotic technologies that contribute to sustainable construction practices.

There is also a burgeoning market for retrofitting existing machinery with robotic capabilities. Startups can innovate by providing modular robotic systems that can be integrated with traditional construction equipment, offering a more accessible entry point for construction firms to explore automation.

Additionally, strategic partnerships with established construction companies can accelerate technology adoption. By collaborating with industry players, startups can gain valuable insights into market needs, test their technologies in real-world conditions, and enhance their credibility in the market.

Strategies for Success: Fundraising and Scaling

For startups in construction robotics, securing funding is a crucial step toward scaling their operations and advancing their technological capabilities. Successful fundraising campaigns hinge on presenting a compelling value proposition, demonstrating market potential, and showcasing technological readiness.

Engaging with venture capitalists and angel investors who have a track record of investing in robotics and construction technology can provide startups with not just capital, but also strategic mentorship. Developing a robust business model that clearly outlines revenue generation, scaling prospects, and cost management is essential to attract serious investors.

Scaling in construction robotics requires a strategic approach to market entry and expansion. Startups should begin by targeting niche markets or specific geographical regions with high acceptance for technological innovation. Building strong relationships with early adopters and continuously gathering feedback will enable them to refine their products and approach broader markets effectively.

Achieving Product-Market Fit and Customer Acquisition

Achieving product-market fit is pivotal for startups in the construction robotics arena. This involves thoroughly understanding the specific needs and pain points of the construction industry and tailoring robotic solutions to address them effectively. Startups must engage in intensive market research and user testing to ensure that their products not only meet technical expectations but are also user-friendly and economically feasible for their target customers.

Customer acquisition strategies should focus on demonstrating tangible benefits through pilot projects and showcasing successful case studies. Organizing workshops and training sessions can help demystify the technology and build confidence in its capabilities among potential clients.

Exploring Unique Aspects of Business Models and Technology

The unique aspects of startups’ business models and technologies can be pivotal in differentiating them from competitors. One approach is adopting a service-oriented model, offering robotics-as-a-service (RaaS) where clients pay based on usage rather than outright purchasing the robots. This reduces the upfront costs for construction firms and makes technologically advanced tools more accessible.

On the technological front, startups can innovate by incorporating the latest advancements in artificial intelligence and machine learning to enhance the performance and adaptability of their robots. Robust data analytics can provide valuable insights into construction processes, enabling more informed decision-making and optimization.

Case Studies and Real-World Examples

Examining successful case studies can offer inspiration and practical insights for startups venturing into construction robotics. An exemplary case is that of SAM (Semi-Automated Mason), a bricklaying robot developed by Construction Robotics, a company that has gained significant attention for its innovative approach. SAM can lay an estimated 3,000 bricks a day, compared to the 1,000 bricks an average mason would manage. This example illustrates the potential gains in productivity and efficiency.

Another notable mention is Fastbrick Robotics, an Australian company known for its Hadrian X bricklaying robot, which uses a 30-meter boom to precisely place bricks using a 3D CAD model. Fastbrick’s approach highlights the importance of precision engineering and advanced planning in developing market-ready construction robots.

Academic Research and Industry Reports

Academic research and industry reports can provide foundational knowledge and future directions for startups in the construction robotics field. Studies often emphasize the broader implications of robotics in improving construction safety, reducing labor costs, and enhancing overall project outcomes. Reviewing such literature can aid startups in identifying key trends, potential pitfalls, and evolving market dynamics.

For instance, research conducted by the Robotics Institute at Carnegie Mellon University explores how advancements in sensor technologies and AI can improve autonomous decision-making in construction robots. Such insights are invaluable for startups looking to incorporate cutting-edge technology into their products.

In conclusion, the integration of robotics in construction processes like bricklaying and plastering represents a groundbreaking shift with immense potential for innovation and disruption. While challenges such as development costs, industry acceptance, and technological complexity must be navigated, the opportunities for startups are abundant. By implementing strategic approaches in fundraising, scaling, customer acquisition, and leveraging unique business models, startups can set the stage for pioneering advancements in construction robotics, ultimately transforming the way we build.