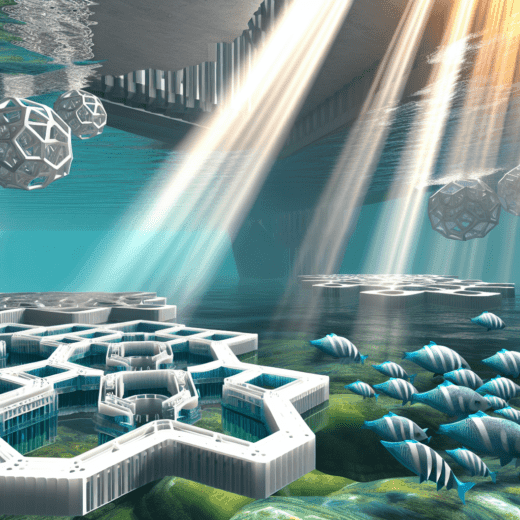

Exploring 3D Printed Fish Farm Structures: A Revolution in Aquaculture

The concept of integrating 3D printing technology with aquaculture is not merely a futuristic fantasy but an emerging reality with immense potential. This integration is set to revolutionize how we approach fish farming through the creation of customizable and durable structures tailored specifically for aquatic environments. The innovative use of 3D printing in developing fish farm structures has the potential to significantly disrupt traditional market dynamics, offering startups unique opportunities and formidable challenges alike. This comprehensive exploration delves into the nuances of this transformation, focusing on innovation potential, market disruption, and strategic approaches crucial for navigating the startup landscape in this domain.

Innovation Potential of 3D Printing in Fish Farming

3D printing, or additive manufacturing, allows for the creation of complex, customizable structures that are well-suited to the varied requirements of fish farming. Traditional fish farm structures often face limitations in terms of modification and scalability due to the constraints of conventional materials and manufacturing processes. With 3D printing, however, structures can be designed with precision to meet specific needs.

One of the major advantages is the ability to design habitats that mimic natural environments. For instance, utilizing intricate designs helps create spaces that resemble coral reefs or oyster beds, encouraging natural behaviors in fish and enhancing ecological sustainability. Beyond this, 3D printing enables the use of eco-friendly materials that can minimize environmental impact. Biodegradable polymers and sustainable composites are being used to create structures that not only support marine life but decompose naturally over time, reducing waste.

Furthermore, 3D printing offers rapid prototyping capabilities. Startups can quickly iterate on designs based on feedback and performance metrics, allowing them to achieve an optimal balance between functionality and cost-effectiveness. This agility accelerates innovation cycles and empowers startups to stay ahead in a competitive market.

Market Disruption and Opportunities

The introduction of 3D printed fish farm structures could disrupt traditional aquaculture markets by lowering costs and introducing new business models. For instance, startups can offer modular designs that farmers can custom-select based on specific needs and environmental conditions, thereby revolutionizing the one-size-fits-all approach of conventional methods. This flexibility enhances customer value and opens up new revenue streams.

Moreover, as global demand for seafood continues to grow, there is increasing pressure on existing aquaculture operations to expand sustainably. By reducing the environmental footprint of fish farming through innovative designs and materials, 3D printed structures broaden the reach of aquaculture into previously unexploited or under-exploited areas. This alleviation of space constraints presents a powerful opportunity for startups to capture new markets and scale their operations.

For instance, an Israeli startup, “ECOncrete,” employs 3D printing technology to produce eco-friendly marine infrastructure. By creating structures that increase marine biodiversity and durability, they have been able to penetrate both aquaculture and coastal protection markets, showcasing the broad applicability and market potential for 3D printed marine structures.

Key Challenges in the Startup Space

Despite the promising potential, startups venturing into 3D printed fish farm structures face several challenges. The technology itself—while rapidly advancing—is still relatively nascent, posing inherent risks in terms of reliability and performance. Moreover, the high initial costs associated with specialized 3D printing equipment and materials can present significant financial barriers to entry.

Another hurdle lies in regulatory approval. Aquaculture, particularly in offshore environments, is subject to stringent regulations regarding equipment, environmental impact, and biosecurity. Startups must navigate this complex landscape to ensure compliance while advocating for regulatory frameworks that accommodate innovative technologies.

Additionally, educating potential customers about the benefits and value of 3D printed structures compared to traditional methods is an obstacle. Adoption often hinges on demonstrating clear and tangible benefits in terms of cost savings, environmental sustainability, and operational efficiency.

Strategies for Success

To overcome these challenges, startups in the 3D printed fish farm structure sector need to adopt strategic approaches that focus on innovation, scalability, and customer engagement. An essential first step is securing funding to invest in Research & Development, allowing companies to refine their technologies and prove their value proposition. Venture capital, government grants, and strategic partnerships with established players in the aquaculture industry can provide the necessary financial backing.

Scaling the business requires a focus on establishing strong supply chains and production capabilities. Startups should aim to optimize their production processes to reduce costs and increase output, making it easier to meet market demand. Collaborations with logistics companies can help ensure efficient distribution and deployment of structures.

Achieving product-market fit is crucial and startups must engage closely with their target audience to understand their specific needs and pain points. Through pilot projects and trials, companies can gather valuable data that informs product development and customization. Customer feedback should influence ongoing design iterations to ensure products address the real challenges faced by fish farmers.

An educational marketing strategy is essential to communicate the unique features and benefits of 3D printed structures. Content marketing, including webinars, white papers, and case studies, can be effective in building awareness and credibility within the industry. Demonstrating successful implementation through real-world case studies, such as those from companies like ECOncrete or others leading the charge, offers compelling evidence for potential customers.

Unique Business Models and Technologies

The novel approach of using 3D printing in fish farming also opens up distinctive business models that capitalize on customization and local production. By offering bespoke design services, where fish farmers can specify features based on their unique requirements, startups can create highly personalized solutions that set them apart from standard offerings.

Moreover, the decentralized nature of 3D printing allows for production facilities to be set up close to end-users, minimizing transportation costs and lead times. This method of local production further allows startups to tailor their offerings based on regional regulations and environmental conditions.

Innovative technologies, such as artificial intelligence and IoT integration, can further enrich 3D printed fish farm structures. By embedding sensors and smart technology, these structures can provide real-time data on water quality, temperature, and other critical metrics, enabling farmers to make informed decisions and optimize conditions for aquaculture.

Case Studies and Examples

A notable example in the sector is a partnership between a Norwegian tech company and a leading aquaculture firm, which has developed customizable fish habitats using 3D printing technology. Their success lies in their ability to combine cutting-edge materials science with precise design capabilities, resulting in structures that enhance fish growth and reduce disease occurrence. By focusing on a continuous feedback loop with their clients, they have consistently improved their product offerings to better serve the aquaculture industry.

Another example is “CoralVita,” a company initially focused on coral reef restoration that has expanded its use of 3D printing into fish farming infrastructure. They have designed structures that not only support marine life restoration but also provide sustainable solutions for fish farming, addressing both ecological and commercial objectives.

Academic Research and Industry Reports

Several academic studies and industry reports highlight the transformative potential of 3D printed structures in aquaculture. Research published in journals such as “Aquacultural Engineering” and “Marine Policy” underscores the advantages of improved habitat design and environmental sustainability offered by 3D printing. Industry reports from organizations like the World Aquaculture Society provide insights into market trends and projections, indicating a growing interest in innovative technologies that enhance aquaculture practices.

Conclusion

The convergence of 3D printing technology with fish farming heralds a new era of sustainable aquaculture practices. By harnessing the capabilities of additive manufacturing, startups are poised to disrupt traditional models and unlock unprecedented opportunities in the industry. While challenges exist in terms of technological readiness, regulatory compliance, and customer education, strategic approaches focusing on innovation, scalability, and customer-centricity can pave the way for success. Through real-world implementations, collaborative initiatives, and an unwavering focus on sustainability, 3D printed fish farm structures could reshape the future of aquaculture, authorizing startups to lead this transformative journey.