Introduction

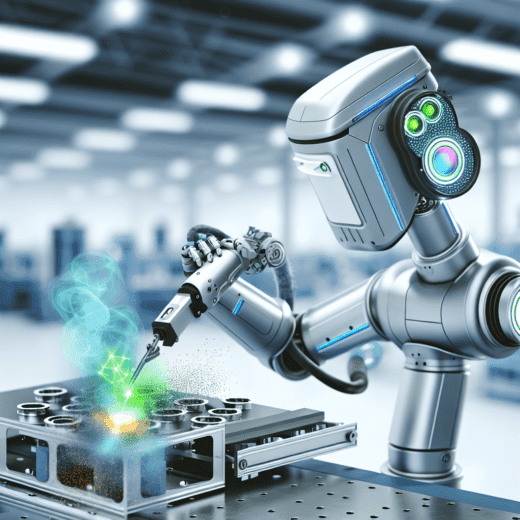

The technological revolution is undeniably changing the manufacturing landscape, with smart welding robots emerging as a pivotal development in enhancing welding accuracy and safety. The fusion of artificial intelligence (AI) and sensors into robotic systems signifies not just a remarkable leap in innovation but also an enduring shift in paradigm for industries heavily reliant on welding processes. For entrepreneurs and investors, the transformative potential of smart welding robots presents both lucrative opportunities and formidable challenges. This detailed exploration delves into the pressing question: How can one leverage the power of smart welding robots to disrupt markets and forge successful startups?

The Innovation Potential of Smart Welding Robots

Smart welding robots symbolize a significant step forward in industrial automation, marrying AI with sensors to ensure precise, consistent, and safer welding operations. Unlike traditional welding methods that depend heavily on human manual skills, these robots can process a range of environmental inputs to self-adjust and correct errors in real-time. This capability is transformative in industries where precision and safety are paramount, such as in aerospace, automotive, and construction.

AI-driven welding robots utilize machine learning algorithms to learn from vast datasets comprising various welding scenarios. Over time, they improve their performance by recognizing patterns and predicting the most effective welding approaches for specific tasks. Sensors extend these capabilities by providing feedback on parameters such as temperature, pressure, and alignment, further contributing to superior outcomes.

Market Disruption: A Transformative Opportunity

The integration of AI-driven robots in welding processes has the potential to disrupt existing market structures considerably. Traditional manufacturing environments often grapple with issues like high labor costs, inconsistent quality due to human error, and stringent safety requirements. Smart welding robots address these concerns by offering cost efficiencies and reliable, repeatable quality that minimizes waste and rework.

Startups entering this space might find fertile ground due to the market’s demand for increased automation and the ongoing labor shortages in skilled welding. With the global welding market anticipated to grow considerably, smart welding robots stand as game-changers capable of capturing significant shares of this expanding market. The opportunity lies not just in developing robots but also in offering comprehensive solutions, such as integrating existing manufacturing lines with AI technology, providing training for workforce adaptation, and ongoing maintenance services.

Challenges: Navigating the Startup Landscape

Despite the captivating opportunities, startups face several hurdles in developing and commercializing smart welding robots. Technical Challenges: Designing robots that can match or surpass human precision in complex welding tasks without sacrificing speed is a significant challenge. The development of advanced algorithms that can efficiently process diverse welding techniques and materials remains an ongoing task. Cost Considerations: The upfront development costs and capital expenditure required for robotics and AI technology integration can be daunting for startups. Balancing investment against eventual returns requires careful strategic planning and financial management. Market Acceptance: Convincing traditional industries to shift to robotic solutions necessitates overcoming entrenched practices and resistance to change. Careful positioning and strategic partnerships can play a crucial role in breaking down such barriers.

Achieving Product-Market Fit

For startups in the smart welding robot sector, achieving product-market fit is critical. Extensive market research is necessary to understand specific customer needs and pain points. By closely collaborating with industry players or potential clients during the development phase, startups can tailor their products to fit exact demands, whether that involves unique welding requirements or integration with existing technology systems.

Case studies of companies like Path Robotics highlight how focusing on customer pain points and continually iterating based on feedback can significantly impact a startup’s success. Path Robotics leveraged AI to design systems that require minimal programming, thus eliminating a major pain point – the need for skilled programmers to operate robotic systems.

Strategic Fundraising for Growth

Securing appropriate funding is essential for the growth of startups developing smart welding robots. Entrepreneurs need to identify suitable investors who understand the technology and its potential impact. Venture capital firms specializing in industrial automation or AI technology can provide not just funding but valuable industry insights and connections.

A successful case in point is Covariant, which raised capital by pitching its AI capabilities not only as a way to automate processes but as a technology that could transform broader sectors beyond welding. Startups should craft compelling narratives about their technology’s future impact to attract investors interested in revolutionary technologies.

Scaling: Moving from Startup to Industry Leader

Scaling in the smart welding robot industry involves expanding the robot’s capabilities, enhancing production, and exploring new markets or industries. One effective strategy is forming alliances with established industrial players, which can provide startups with the necessary scale and legitimacy to penetrate new sectors.

Consider the approach of Ready Robotics, which created platforms easily adaptable to various industry needs, significantly broadening its market reach. Offering flexibility and ease of customization can make a startup’s product appealing to a wider audience and facilitate rapid scaling.

Customer Acquisition: Building a Loyal Customer Base

Establishing a loyal customer base requires strategic marketing and customer engagement approaches. Startups should showcase the tangible benefits of their technology – increased safety, cost savings, and improved productivity – through targeted marketing campaigns and case studies that highlight successful implementations.

Universal Robots excelled in customer acquisition by fostering a community around its product through workshops, forums, and training sessions, thereby not only educating potential users but also cultivating brand loyalty and advocacy.

Unique Aspects of the Business Model and Technology

Startups in smart welding robotics can set themselves apart by offering unique value propositions, such as subscription-based models that decrease initial investment hurdles for clients or value-added services like remote monitoring and analytics powered by AI. These business model innovations can build long-term relationships with clients and create recurring revenue streams.

Technological Innovation: Developing more intuitive AI systems that require minimal human intervention enhances the attractiveness of welding robots. Startups should focus on R&D to continually push the boundaries of AI and sensor technology, ensuring their offerings remain cutting-edge.

A notable example is Bright Machines, which emphasizes automation software over hardware, effectively differentiating itself by delivering flexible, software-driven automation solutions that adapt to evolving manufacturing needs.

Real-World Case Studies

Successful case studies serve as powerful learning tools for startups. Automata, a robotic company, leverages sophisticated robotics for precision-dependent tasks in the welding industry, showcasing successful product implementation and scaling strategies. Their focus on affordable, scalable solutions reflects a deep understanding of market needs and an effective approach to overcoming common industry challenges.

Academic Research and Industry Reports

The development of smart welding robotics is underpinned by extensive academic research and industry insights. Key reports from institutions such as the Association for Advancing Automation (A3) and International Federation of Robotics (IFR) provide valuable data on industry trends, technological advancements, and market predictions. Startups can leverage these insights to align their strategic plans with industry trajectories and emerging opportunities.

Conclusion

The journey of developing and commercializing smart welding robots requires a delicate balance of innovation, financial acuity, and strategic foresight. As industries continue their march towards increased automation, the role of smart welding robots in reshaping welding processes and enhancing safety and accuracy becomes unequivocal. By understanding market needs, effectively communicating value propositions, and navigating technical challenges, startups can position themselves not only as players but as leaders in this transformative field. The ongoing technological advancements herald a bright future for smart welding robots, promising substantial rewards for those daring to seize the opportunity.