Introduction to Factory Worker Assistance Robots

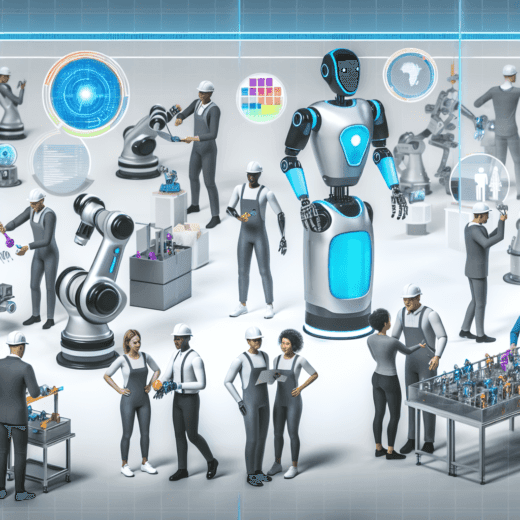

As the industrial sector races towards automation, Factory Worker Assistance Robots (FWAR) emerge as a groundbreaking category reshaping the traditional boundaries of manufacturing. Designed to synergize with human capabilities, these robots handle physically demanding tasks—lifting, stacking, sorting—that would otherwise lead to human fatigue. Not only do FWARs enhance productivity, but they also represent a seismic shift in market dynamics, offering transformative opportunities for startups in the robotics sector.

The Innovation Potential of FWARs

At the heart of FWARs lies the promise of innovation. The robotics industry has long been fascinated by the blend of human intuition with machine power, and FWARs exemplify this synthesis. Unlike their fully autonomous counterparts, these robots are designed to assist rather than replace, fostering a collaborative environment known as human-robot collaboration. This could lead to a reimagining of manufacturing processes, where the human workforce becomes more nimble and versatile.

Key innovations include advanced sensor technology for situational awareness, AI-driven decision-making algorithms, and ergonomic designs that complement human biology. Recent innovations, such as Boston Dynamics’ Stretch, reflect the potential of FWARs. This robot automates box handling in warehouses, significantly reducing worker strain while maintaining efficiency. Such developments are not only innovative but also promise to redefine industrial norms and expectations.

Market Disruption and Opportunities

The FWAR sector is positioned for substantial market disruption. With the global robotics market projected to reach $275 billion by 2025, FWARs are primed to attract significant investment. This is due to their applicability across various industries—from automotive assembly lines to electronics manufacturing and beyond.

Startups in this space face an exciting array of opportunities. By addressing real-world challenges such as labor shortages and increasing production demands, FWARs can carve out a niche in the labor-displacing anxiety of automation. Companies like Rethink Robotics, with its Baxter and Sawyer robots, demonstrate successful entry points by focusing on cost-effective, easily deployable robots that integrate seamlessly into existing processes.

Key Challenges in the FWAR Sector

However, success in the FWAR sector is fraught with challenges. A primary concern is ensuring safety and efficiency—robots must operate smoothly alongside humans without increasing risk. Designing systems that are reliable and adaptable to various tasks is crucial. Moreover, overcoming scepticism towards automation among factory workers presents a socio-economic challenge.

Startups must also navigate the complexities of regulatory compliance and data privacy issues, which are increasingly paramount as these robots become more interconnected and reliant on data sharing.

Strategic Approaches for Startups

Fundraising and Financial Strategy

Raising capital in a competitive landscape requires a clear value proposition. Startups should focus on demonstrating how their FWAR technology can save costs and enhance productivity. Partnerships with major manufacturing firms can offer financial backing and credibility. For instance, Fetch Robotics publicly aligned with major distribution centers to showcase its capabilities, securing substantial funding.

Achieving Product-Market Fit

Understanding customer needs and adapting products swiftly is essential for achieving product-market fit. Early-stage startups should engage potential clients through pilot programs, collecting valuable feedback. This approach allows for iterative development reflecting market demands. The iterative cycle used by Universal Robots in developing their collaborative arm robots has set a precedent for success.

Scaling and Growth Strategies

Scaling requires transitioning from a proven product to mass market capabilities. Manufacturing partnerships and streamlined production processes are pivotal. Moreover, leveraging data analytics to refine and localize product offerings can enhance scalability. Startups must be adaptable, investing in infrastructure that supports expansion into different geographic markets.

Customer Acquisition and Retention

Targeted marketing and building strong client relationships are essential for customer acquisition. Offering training programs for employees ensures smooth integration of FWARs and fosters trust. Companies like Robotiq have excelled by providing comprehensive support and education, ensuring client satisfaction and retention.

Distinctive Business Models and Technologies

Unique business models set successful startups apart. Subscription models for FWAR software and maintenance, or robots-as-a-service (RaaS), create steady revenue streams. Additionally, utilizing open-source platforms for robot development can reduce costs and foster a collaborative ecosystem for innovation.

Real-World Case Studies

Successful FWAR-focused startups provide invaluable insights. One notable example is Locus Robotics, which specializes in autonomous mobile robots for warehouses. By enabling workers to manage tasks more efficiently, Locus Robotics enhances operational throughput significantly. Through strategic partnerships and continuous innovation, it has emerged as a leader in the sector.

Academic Research and Industry Insights

Academic institutions contribute significantly to the evolution of FWARs. Studies from universities such as MIT highlight the importance of ergonomic design and machine learning in enhancing human-robot interaction. Industry reports suggest that FWAR adoption could improve factory productivity by up to 30%, highlighting immense potential.

Conclusion: The Path Forward for FWAR Startups

The journey of FWARs is one of continuous innovation and adaptation. As startups navigate this dynamic landscape, a focus on safety, human interaction, and market understanding will remain critical. The fusion of advanced robotics with human labor not only promises economic efficiency but also an evolution of modern manufacturing. Entrepreneurs diving into this space carry the potential to transform industries, redefine labor dynamics, and shape the future of work on a global scale.