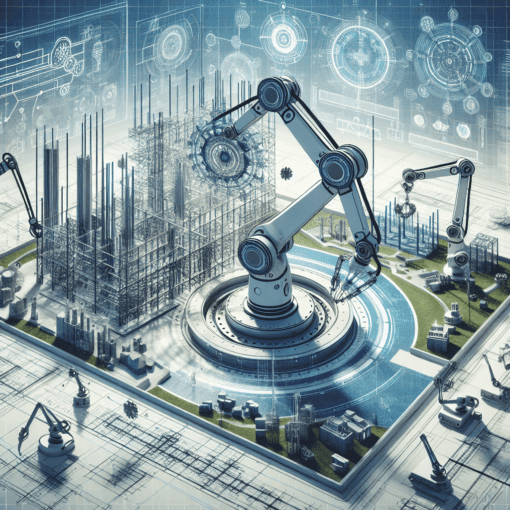

Understanding the Landscape: 3D Printing Robots in Construction and Manufacturing

In recent years, the merger of robotics and 3D printing has heralded a new frontier in both construction and manufacturing industries. This technology—integrating robotic arms with 3D printers—offers a revolutionary approach to traditional fabrication methods, marking a significant shift in how structures and components are produced. The potential to utilize robotic arms for large-scale 3D printing represents not just an evolution of existing practices but a seismic shift with the potential to redesign the landscape altogether. This innovation promises unparalleled efficiency, customization, and a reduction in material waste, positioning itself as a game-changer in terms of sustainability and cost-effectiveness.

The Innovation Potential of Large-Scale 3D Printing Robots

The capability to utilize robotic arms for 3D printing on a large scale in construction and manufacturing comes with immense promise. Imagine seamless construction in remote or challenging environments where building materials can be limited or inaccessible. 3D printing robots can circumvent these hurdles by using locally sourced materials or recycled content, paving the way for more sustainable and responsible construction practices.

From a manufacturing standpoint, these robots can redefine production lines ensuring faster turnaround times and less dependency on human labor for repetitive tasks. For example, companies like ICON in the United States have already succeeded in 3D printing homes with the help of robotic arms, setting a precedent in the construction industry by lowering costs and reducing building time significantly.

Furthermore, 3D printing robots excel in customization. Unlike traditional manufacturing techniques that are generally designed for mass production, 3D printing allows for unique, customized outputs without additional costs or delays. This opens up limitless possibilities for designers and architects, pushing the boundaries of creativity and functional design.

Market Disruption: Changing the Rules of the Game

As these technologies mature, they are poised to disrupt existing markets fundamentally. Real estate developers, manufacturers, and city planners are beginning to recognize the unique benefits of incorporating 3D printing robots into their workflows. In the construction industry, 3D printing can address labor shortages—a critical challenge faced globally—by automating build processes and reducing the need for manual labor on-site.

Manufacturing markets are witnessing similar disruptions. The ability to quickly fabricate complex parts and mechanisms on-demand directly translates to a competitive edge. Companies like MX3D, known for their 3D-printed steel bridge in Amsterdam, demonstrate the potential to create complex metal structures which were once thought impossible.

Moreover, market disruption isn’t limited to production processes alone; it’s redefining supply chains. The decentralization of manufacturing due to 3D printing allows for localized production, reducing transportation costs and carbon footprints. Such disruption inevitably leads to shifting consumer preferences and market demands, compelling traditional industries to adapt or risk obsolescence.

Key Challenges: The Roadblocks Ahead

Despite the burgeoning potential, the integration of large-scale 3D printing robots is not without its challenges. One of the most significant obstacles is the initial capital investment. Developing or acquiring advanced robotic 3D printers involves substantial expenses, not only in terms of machinery but also in setting up the necessary infrastructure to support them.

Another challenge lies in regulatory hurdles. Construction, in particular, is a meticulously regulated industry, with stringent codes and standards that new technologies must meet. Navigating these regulations and gaining approval for widespread use of 3D-printed structures remain hurdles for entrepreneurs in this space.

Furthermore, there is an ongoing skills gap within the labor force. Operating and maintaining these sophisticated machines demands a skilled workforce adept in both robotics and 3D printing technology. Bridging this skills gap requires extensive training and education initiatives, often posing a significant challenge for new startups.

Unique Opportunities in the Startup Ecosystem

For startups, the ability to innovate with robotic 3D printing presents unique opportunities. Enterprising companies can lead the charge in niche applications, such as disaster relief housing, where rapid deployment of printing robotics can provide immediate solutions. This adaptability to emergent needs provides startups with a crucial advantage over larger, less nimble entities.

Startups have the ability to integrate advancements in artificial intelligence and machine learning with 3D printing technologies, enhancing precision and efficiency. Autonomous 3D printers, capable of self-correcting errors in real-time, allow startups to produce higher-quality outputs that conform to stringent industry standards more efficiently.

Moreover, partnerships present untapped potential. Collaborating with industry leaders in construction or materials engineering can offer startups the opportunity to refine and showcase their technologies on larger scales. Such strategic alliances can bolster credibility and provide access to broader markets.

Strategies for Success: From Concept to Market

Fundraising

A cornerstone strategy for startups in this domain is effective fundraising. The capital-intensive nature of developing robotic 3D printing technology necessitates securing substantial investment. Developing a comprehensive business plan that clearly outlines the potential and scalability of the technology is vital in attracting investors.

Venture capitalists, increasingly interested in sustainable and disruptive technologies, present a promising source of funding. Engaging with niche investors who have a clear understanding of the technology’s trajectory and industry impacts can facilitate smoother fundraising processes. Moreover, governmental grants aimed at technological innovation and sustainability offer additional funding pathways.

Scaling Operations

Beyond securing funds, startups must focus on scalable operations. Efficient scaling requires establishing robust supply chains and reliable partnerships with technology providers and suppliers. It is essential to nurture relationships with suppliers who can deliver high-quality materials consistently, ensuring the production lines remain uninterrupted during scaling phases.

Investing in research and development to continually refine 3D printing technologies should be a priority. Incorporating feedback loops from early adopters and iterating on the technology based on practical application tests can lead to enhancements that facilitate smoother scalability.

Achieving Product-Market Fit

Product-market fit is critical. Understanding the target market’s specific needs and challenges allows startups to tailor their innovations accordingly. Comprehensive market research is essential to determine where robotic 3D printing can solve the most pressing industry problems or unlock new efficiencies.

The pivoting ability is another essential skill; adapting the product in response to market feedback demonstrates flexibility and responsiveness—a trait valued highly by consumers and investors alike.

Customer Acquisition

Effective customer acquisition strategies can dramatically influence a startup’s success trajectory. Building a strong brand identity that emphasizes innovation, reliability, and sustainability can resonate well with potential customers. It’s equally important to develop demonstrative case studies showcasing successful implementations and tangible benefits, thereby building trust and credibility.

Networking within industry-specific groups and forums can also serve as an effective customer acquisition strategy. Offering workshops, webinars, and live demonstrations on the practical applications of 3D printing robots can attract initial customers and build an engaged community.

Distinctive Business Models

Crafting a distinctive business model that aligns with technological offerings can set a startup apart. A subscription-based model for software and hardware updates provides ongoing revenue streams and ensures customers remain up-to-date with the latest advancements. Alternatively, a pay-per-use model could lower the entry barrier for smaller firms interested in adopting 3D printing capabilities but deterred by significant upfront costs.

Case Studies: Pioneering Startups in 3D Printing Robotics

ICON and Apis Cor are two notable startups leading the charge in 3D printing robotics within the construction domain. ICON has leveraged funding to develop a proprietary approach to 3D home building, resulting in partnerships with government agencies and housing sectors to address affordable housing shortages. Their success lies in a clear understanding of market needs—low-cost, environmentally friendly housing solutions—and strategically aligning their technology to address these requirements.

Apis Cor, known for their development of the first on-site 3D-printed house, exemplifies innovation within extreme environments, tackling harsh climates in Siberia in their early projects. By perfecting technologies to cope with these environments, Apis Cor has expanded possibilities not only in real estate but also in potential applications on extraterrestrial surfaces such as Mars, a bold vision supported by collaborations with NASA.

Academic Insights and Industry Reports

Academic research supports the potential of 3D printing robots, predicting significant industry growth over the next decade. According to a report by MarketsandMarkets, the 3D printing market is projected to grow from $12.6 billion in 2021 to $34.8 billion by 2026. Robotics and automation are integral to this expansion, underscoring the importance of adaptable, large-scale solutions.

Additionally, MIT’s research into construction automation highlights the sustainability benefits arising from reduced material waste and emissions, further validating robotics’ role in sustainable construction practices. Industry reports and academic journals provide a wealth of information, bolstering startups’ cases for required technology investments and underscoring the pressing need for innovative solutions in construction and manufacturing.

Conclusion: Pioneering the Future with 3D Printing Robots

As the intersection of robotics and 3D printing unfolds, a revolution in construction and manufacturing becomes imminent. For startups, the task lies not only in capitalizing on this innovation potential but also in navigating the complex landscape of challenges and opportunities it heralds. Establishing a strong foundation through strategic fundraising, achieving product-market fit, and employing innovative customer acquisition strategies will set the stage for success.

By drawing inspiration from successful case studies and aligning closely with industry research, startups can lead the charge in redefining traditional manufacturing and construction paradigms. Embracing this cutting-edge technology signals not just an evolution within industries but a transformative movement with the potential to reshape the very fabric of industrial production and infrastructure development.