Introduction

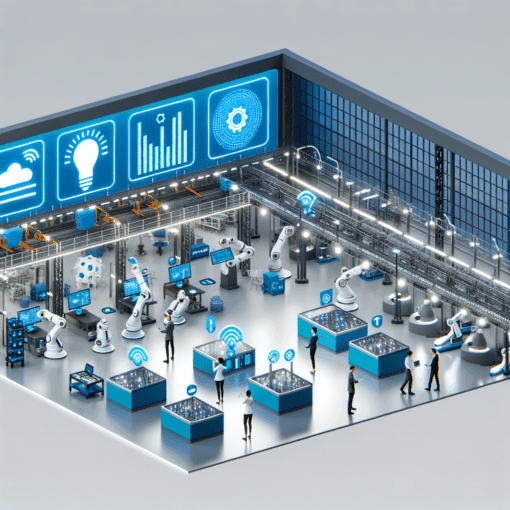

In an era where technology is evolving at an unparalleled pace, the concept of smart factories with connected production lines represents a forefront innovation in the manufacturing industry. These smart factories, powered by the Internet of Things (IoT), advanced robotics, artificial intelligence (AI), and big data analytics, are revolutionizing how products are produced, managed, and distributed. The startup ecosystem has been significantly impacted by this transformation, offering a plethora of innovation potential, market disruption possibilities, and unique challenges.

Innovation Potential

The innovation potential of smart factories with connected production lines is vast. They offer enhanced flexibility and efficiency, leading to higher productivity and reduced operational costs. Smart factories leverage IoT to connect machines, systems, and humans, creating a seamless ecosystem where data flows effortlessly, enabling real-time decision-making and predictive maintenance. This interconnectedness allows for greater customization of products without sacrificing efficiency, which is a game-changer in industries like automotive and consumer electronics.

Moreover, AI and machine learning algorithms analyze massive amounts of data generated by production lines, identifying patterns and optimizing processes. This not only improves quality control but also reduces waste, contributing to sustainability goals. For startups, entering the smart factory space offers the chance to create cutting-edge solutions that can integrate seamlessly into existing production systems or build new, innovative factories from the ground up.

Market Disruption

Smart factories significantly disrupt traditional manufacturing models. By minimizing human intervention and utilizing automation, these factories can operate 24/7, increasing output and reducing labor costs. This shift enables startups to compete with larger, established firms by offering lower-priced, high-quality products. Additionally, the geographical flexibility offered by smart factories allows startups to set up operations closer to their customer base, reducing shipping costs and delivery times.

Furthermore, as consumers demand personalized products, smart factories enable mass customization, profoundly impacting the distribution of products and services. This personalization trend shifts power from manufacturers to consumers, forcing companies to adapt their offerings continually. For startups, this environment provides an opportunity to innovate quickly, respond to market demands, and capture niche markets that larger players may overlook.

Key Challenges

Despite their numerous advantages, smart factories also present significant challenges. One of the primary concerns is cybersecurity. As factories become more interconnected, they are also more vulnerable to cyberattacks. This necessitates robust security protocols to protect sensitive data and ensure continuous operations. Startups must prioritize cybersecurity from the outset to build trust with their customers and partners.

Another challenge is the high initial investment required to set up smart factories. The cost of acquiring the necessary technology, such as sensors, robotics, and AI systems, can be prohibitive for startups with limited resources. This financial burden can hinder their ability to scale operations quickly and sustainably. Additionally, there is a skills gap within the workforce. Advanced manufacturing technologies require expertise that is not readily available in the current labor market, necessitating investment in training and education.

Unique Opportunities for Startups

Despite challenges, the startup space presents unique opportunities in the realm of smart factories. One such opportunity is in niche market customization. Startups can develop unique product offerings tailored to specific consumer needs, which larger companies might find too complex to manage. This ability to offer on-demand customization can create a competitive advantage.

Partnerships with established industry players offer another avenue for growth. By collaborating with companies that have existing infrastructure but lack agility, startups can leverage their innovative technologies to improve production efficiency and product development. Such partnerships can provide startups with valuable resources, including funding, mentorship, and market access.

Fundraising Strategies

Securing funding is vital for startups aiming to explore smart factory solutions. Venture capital is a common avenue, with investors increasingly interested in technology that enhances productivity and sustainability. To attract venture capital, startups should demonstrate a solid business model, scalability potential, and a clear understanding of their market.

Crowdfunding is another viable option. By engaging with a community of early adopters and tech enthusiasts, startups can generate funding while simultaneously validating their product-market fit. Building a strong online presence and telling a compelling story about the benefits and innovation potential of their technology can help in successful crowdfunding campaigns.

Scaling and Achieving Product-Market Fit

Scaling a smart factory startup involves expanding operations while maintaining efficiency and quality. This requires a strategic approach to growth, focusing on optimizing production processes and leveraging technology to meet increasing demand. Achieving product-market fit is crucial, as it ensures that the product addresses a genuine need and resonates with the target audience.

Startups should prioritize customer feedback and use iterative development processes to refine their offerings continually. By involving customers in the product development process, startups can create solutions that are perfectly aligned with market needs, enhancing customer satisfaction and fostering loyalty.

Customer Acquisition

Effective customer acquisition strategies are critical for the success of smart factory startups. Building a robust digital marketing strategy that highlights the unique advantages of smart factory solutions can capture the attention of potential clients. Networking at industry events and establishing partnerships with key players can also open doors to new opportunities and customer bases.

Offering trial periods or pilot programs allows potential customers to experience the benefits firsthand, increasing the likelihood of converting leads into long-term clients. Providing exceptional customer service and support further enhances customer acquisition efforts, as it builds trust and encourages word-of-mouth referrals.

Distinctive Aspects of the Startup’s Business Model or Technology

Startups in the smart factory space often differentiate themselves through unique business models focused on subscription services or pay-as-you-go models. These approaches lower the barrier to entry for customers who may be hesitant to invest heavily in new technologies upfront. Additionally, startups can focus on developing proprietary algorithms or AI-driven solutions that optimize specific aspects of the production process, providing them with a competitive edge.

Open-source collaboration is another distinctive aspect. By contributing to the open-source community, startups can accelerate innovation, enhance their credibility, and attract talent interested in cutting-edge projects. This collaborative approach can drive rapid technological advancements and create a vibrant ecosystem of innovation.

Case Studies: Success Stories in the Space

Several startups have successfully navigated the complexities of smart factories. One such example is [Startup X], which developed a scalable IoT platform for factory automation. Their solution streamlined production processes, reducing downtime by 20% and increasing overall efficiency. By securing partnerships with key industry players, they expanded rapidly and attracted significant venture capital investment.

Another notable example is [Startup Y], which focused on AI-driven predictive maintenance solutions. By offering a cloud-based platform that analyzes machine data to predict failures, they saved clients substantial maintenance costs and reduced unexpected disruptions. Their innovative approach quickly gained traction, leading to a strong customer base and international expansion.

Academic Research and Industry Reports

Academic research and industry reports provide valuable insights into the development and implementation of smart factories. Studies from leading universities have highlighted the importance of integrating human-centric AI, ensuring that technology complements rather than replaces human workers. This approach not only maintains job security but also maximizes the potential of both human and machine capabilities.

Industry reports from organizations like McKinsey and Gartner emphasize the transformative potential of smart factories in achieving operational excellence. These reports underscore the need for startups to focus on sustainability and digital integration to remain competitive in a rapidly evolving market.

Conclusion

Smart factories with connected production lines represent a significant leap forward in the manufacturing industry, offering startups immense potential for innovation and disruption. While challenges exist, such as cybersecurity concerns and high initial investments, the opportunities for differentiation and growth are substantial. By employing effective fundraising strategies, focusing on scaling and product-market fit, and implementing distinctive business models, startups can thrive in this dynamic ecosystem. Case studies of successful startups provide valuable lessons, and academic research guides the path forward, ensuring that technology continues to enhance manufacturing capabilities. As the industry evolves, smart factories will undoubtedly play a crucial role in shaping the future of production and distribution, offering entrepreneurs and investors exciting prospects.